Our Manufacturing Units

Our Facilities

PROCESS CONTROL ROOM

- Fully integrated PLC driven - Automatic blending)

PROCESS AREA

- Dedicated process lines for multiple blending

Captive DM & RO Plant

- Captive DM & RO Plant For Demineralised Water

PROCESS TANKS

- Tailor Made, Spl.Closed Process Tanks With Coaxial Mixing Technology

- High Resolution Mass Metering Systems For Accurate Dosing

BULK STORAGE TANK

- Tank Farm for Bulk Storage CAPACITY : 500 mt.

- Electronic Weigh-Bridge Avery Make CAPACITY : 60 mt.

MOULDING AREA

- In-house blow injection moulding for small packs

DISTRIBUTION NETWORK

- Company owned tank lorries for bulk transportation

STORAGE AREA

- Dedicated storage area for RM and FG

- 100% power back up

Packaging Area

- A wide area of packaging of Coolants & Brake Fluids.

Printing Area

- In house printing of product labels and posters.

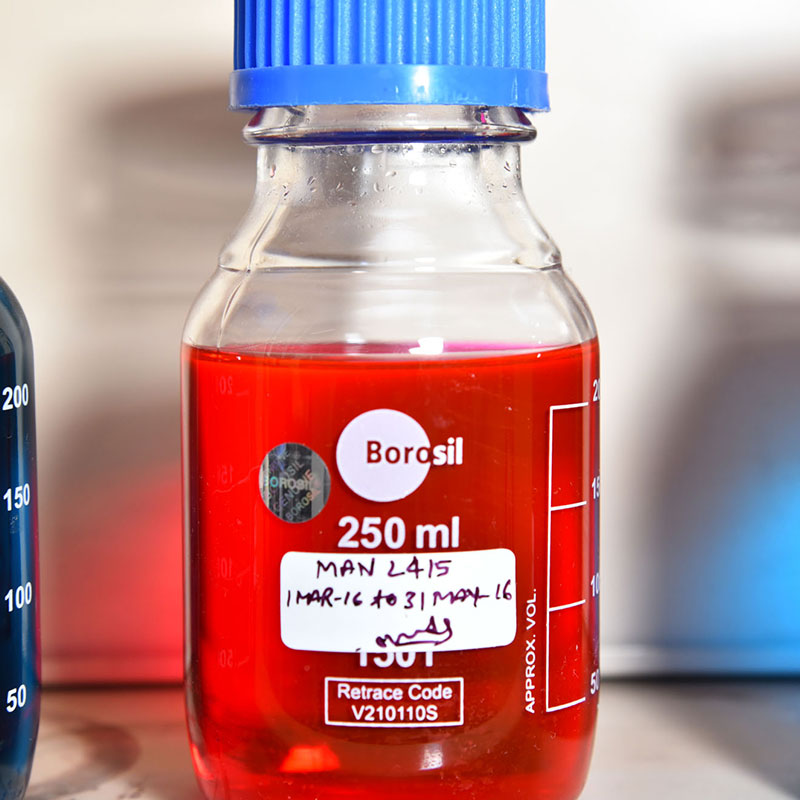

Research & Development LAB

ION CHROMATOGRAPH

- Chromatographic & Spectrometric Analysis Lab

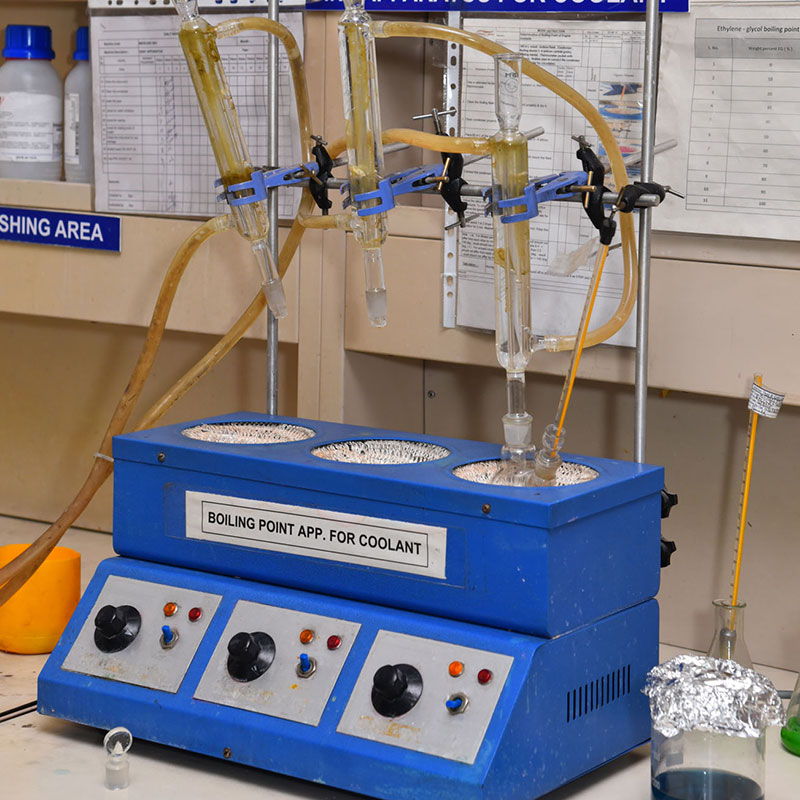

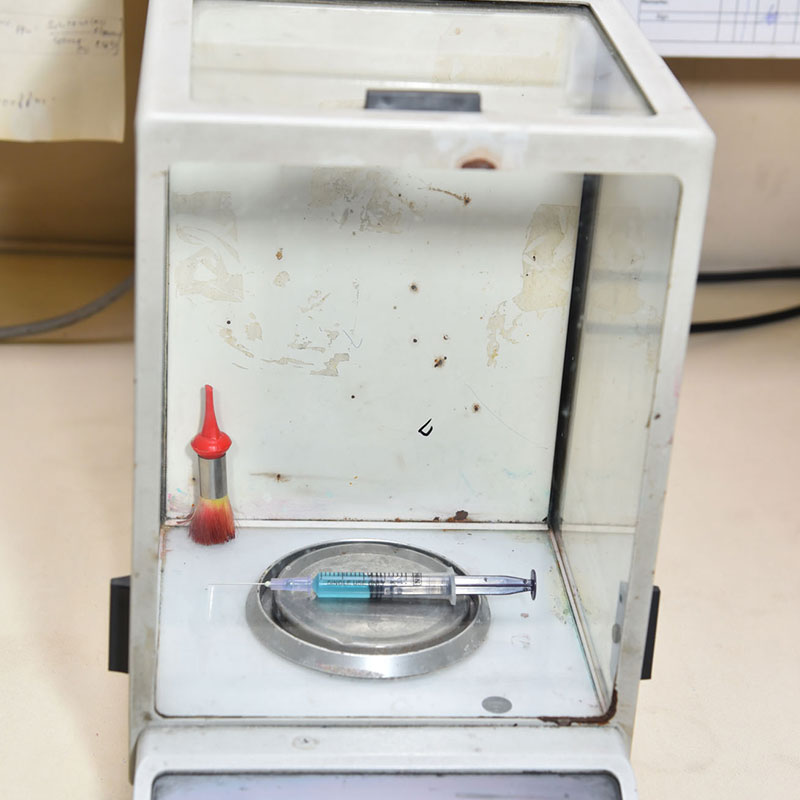

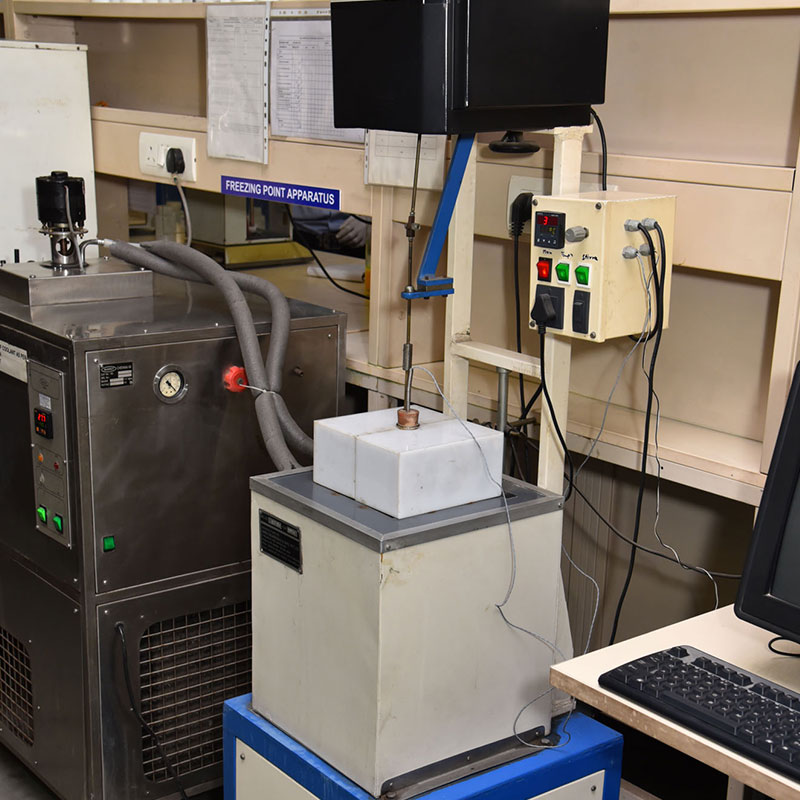

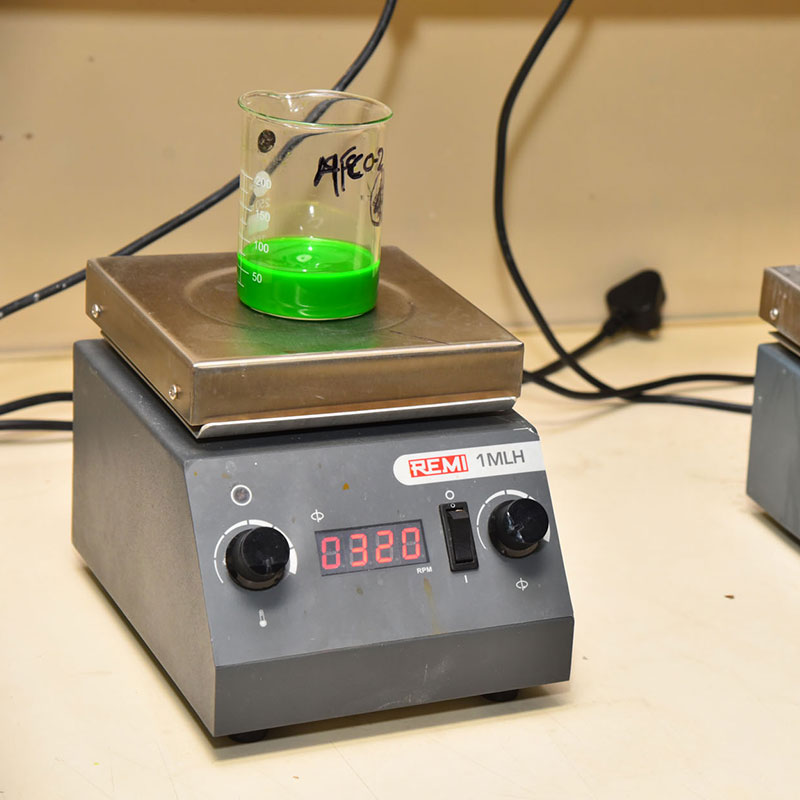

Quality Controls

- Sophisticated Process Control Lab With 100% Testing Facilities As Per International Standard (ASTM, JIS, SAE & BIS) For Both - Anti-Freeze Coolants & Brake Fluid

- Dedicated Corrosion Testing Lab

Autolab Galvanostat

- Specially Set Up Galvanostatic Corrosion Testing Lab

LONG TERM DYNAMIC

GLASSWARE STATIC CORROSION

HEAT REJECTION CORROSION